What measures are appropriate for sealing the inevitable air gaps between an I/O connection’s attachment point on the panel or “skin” of an enclosure and the ambient environment of the application? The answer, as with most things, is “it depends”. In this piece, we will focus not on the more robust versions of interconnects that are IP67 or above but more strategies that assist in vibration mitigation, dust, and light moisture ingress as well as grounding. There are many types of gasket materials available in the market, virtually all of which can be adjusted for properties of thickness, conductivity, conformal geometries, adhesion and service life.

What measures are appropriate for sealing the inevitable air gaps between an I/O connection’s attachment point on the panel or “skin” of an enclosure and the ambient environment of the application? The answer, as with most things, is “it depends”. In this piece, we will focus not on the more robust versions of interconnects that are IP67 or above but more strategies that assist in vibration mitigation, dust, and light moisture ingress as well as grounding. There are many types of gasket materials available in the market, virtually all of which can be adjusted for properties of thickness, conductivity, conformal geometries, adhesion and service life.

Conductive or Dielectric

The product in the photograph was developed for an application that required both a conductive foam to facilitate grounding between the connector shell ground and the panel but also that have a permanent adhesive on the connector side so that it could be applied prior to installation in the panel. This RoHS compliant, UL 94 V-Rated material is custom die cut out of an open-celled Polyurethane foam that provides shielding effectiveness of up to 138 dB @ 1 GHz. It could also be made in a dielectric foam of different thickness and be secured only by the pressure between the inner wall of the enclosure and the connector face when installed.

The product in the photograph was developed for an application that required both a conductive foam to facilitate grounding between the connector shell ground and the panel but also that have a permanent adhesive on the connector side so that it could be applied prior to installation in the panel. This RoHS compliant, UL 94 V-Rated material is custom die cut out of an open-celled Polyurethane foam that provides shielding effectiveness of up to 138 dB @ 1 GHz. It could also be made in a dielectric foam of different thickness and be secured only by the pressure between the inner wall of the enclosure and the connector face when installed.

Quite often there are applications where a less than IP67 level of Ingress Protection is appropriate. In the photo above a foam gasket that is used to seal a USB Type C cable with thumbscrews to an Intel D435 Camera used in a material handling robot. The application of the gasket assists in sealing the area around the Type C female connector on the camera as well as mitigate vibration of the USB type C interconnect while the robot is moving.

Often times vibration is the primary concern of the application engineer. In this case, a thin, silicone layer between then the enclosure wall and the connector being applied to it will do the trick. The photo to the right shows just that with a Positive Lock USB Type C connector that is IP67 when mated. However, the addition of the silicone gasket between the backside of the panel mount connector and panel allows for a nice anti-vibration strategy.

Often times vibration is the primary concern of the application engineer. In this case, a thin, silicone layer between then the enclosure wall and the connector being applied to it will do the trick. The photo to the right shows just that with a Positive Lock USB Type C connector that is IP67 when mated. However, the addition of the silicone gasket between the backside of the panel mount connector and panel allows for a nice anti-vibration strategy.

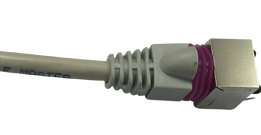

A final approach is a connector conformal gasket can be designed (usually out of Silicone for its elasticity) that can be slipped unto a male connector before it is installed into its receptacle. The purple silicone gasket is sized for an RJ45 male plug and provides an IP55 dust seal between the plug and the jack.

So if you are looking for either an easier and potentially less expensive approach to sealing your panel mounted I/O or more elegant way to grounding the connector shell to the panel the right form of gasket may be the solution you’re looking for. Please feel free to comment or send your inquiry to sales@ocp.com.

So if you are looking for either an easier and potentially less expensive approach to sealing your panel mounted I/O or more elegant way to grounding the connector shell to the panel the right form of gasket may be the solution you’re looking for. Please feel free to comment or send your inquiry to sales@ocp.com.